Muffler Assembly Rt & Left

- Green Hornet

- 100+ Posts

- Posts: 606

- Joined: Sat Aug 26, 2006 8:53 pm

- Location: No Name City, No Where Land, USA

- Contact:

Muffler Assembly Rt & Left

I was changing oil and cleaning Plugs yesterday and noticed cracks in the metal covering the muffler in the corner areas where the screws attach the cover to the muffler.

I asked Maule for a price and delivery date.

Does anyone have any inputs regarding this repair. The right side is cracked at both corners and the left at one corner. Not to much holding the right side together, maybe one screw and the lip on top and I am not sure what on going on below or behind the muffler.

I appreciate all inputs.

I asked Maule for a price and delivery date.

Does anyone have any inputs regarding this repair. The right side is cracked at both corners and the left at one corner. Not to much holding the right side together, maybe one screw and the lip on top and I am not sure what on going on below or behind the muffler.

I appreciate all inputs.

-

MikeW

- 100+ Posts

- Posts: 257

- Joined: Sat Aug 26, 2006 11:02 pm

- Location: Alaska

- Contact:

These mufflers are very prone to cracking. I would probably take the shroud (cover) off on both sides and take a real close look at both mufflers, particularly around any welded areas. If there are any cracks the whole unit should probably be taken off and rewelded. I had this done last annual for about 250.00. If there are no cracks in the manifold I think all you need is a new heater shroud.

Mike

Mike

-

a64pilot

- 100+ Posts

- Posts: 1773

- Joined: Tue Aug 29, 2006 6:53 am

- Location: ALbany Ga., KABY

- Contact:

The heater shroud is non-structual, stop drill the cracks or if they are really bad, weld them or make new ones. They don't have to be air tight. Now the steel part underneath the shroud is very important and must be airtight or you will get CO poisoning. It's usually the back side of the muffler that cracks because the pipes hang on them. If you tighten the clamps that hold the pipe to the muffler they will crack for sure. The pipe should be a sloppy loose fit to the muffler, it's the pin in the clamp that holds the pipe to the muffler, not the clamp. While you have the muffler off, shake it and see if it rattles and / or look into the back side of it with a flashlight. If the baffle is missing or rattling around inside of the muffler your'e either going to have to replace the baffle or the muffler. Running it without the baffle will cause it to burn through the muffler, heat shroud and may even burn a hole through the cowling. Of course you won't realize this is going on because you will be breathing CO at the time

All of this should have been done at the annual of course.

All of this should have been done at the annual of course.

- Green Hornet

- 100+ Posts

- Posts: 606

- Joined: Sat Aug 26, 2006 8:53 pm

- Location: No Name City, No Where Land, USA

- Contact:

My annual is due in October, 3/1/2 months. I have a carbon monoxide detector and so far so good. Of course I am hoping it is only the shrouds ( heat shields) but all will be checked. I might as well do it now these fires have visibility to less than 3SM.

Of course they are calling it HAZE! Only occasionally does anyone reference SMOKE.

Of course they are calling it HAZE! Only occasionally does anyone reference SMOKE.

- 210TC

- 100+ Posts

- Posts: 733

- Joined: Fri Jan 12, 2007 7:58 pm

- Location: New Braunfels, Tx

- Contact:

The exhaust and fuel system within the engine compartment should be kept in nothing but first class condition.

I give my exhaust and fuel system an annual inspection at each oil change.

Inspect, Inspect and Inspect again.

Sometimes when you have a system welded up it pulls or draws the metal a little. All the slip/bolted fitting have to be PERFECT if not it will re crack prematurely. I would ask the shop that would perform the welding in advance if it does not fit properly would they come out with torches to make field adjustments, if you cannot.

Sojorrn, did you get your new o2 system?

I give my exhaust and fuel system an annual inspection at each oil change.

Inspect, Inspect and Inspect again.

Sometimes when you have a system welded up it pulls or draws the metal a little. All the slip/bolted fitting have to be PERFECT if not it will re crack prematurely. I would ask the shop that would perform the welding in advance if it does not fit properly would they come out with torches to make field adjustments, if you cannot.

Sojorrn, did you get your new o2 system?

David

www.Landshort.com

www.Landshort.com

- Green Hornet

- 100+ Posts

- Posts: 606

- Joined: Sat Aug 26, 2006 8:53 pm

- Location: No Name City, No Where Land, USA

- Contact:

David,

I did get the O2 system . Per your recommendations I have the Sky OX the SK11-50 big bottle. I believe you said the refill cost the same no matter what the size. I got a chance to use it on my way to McCAll, ID. I was at 9,500 ft.. I had forgot about until half way through the flight but when I put it on I felt an almost immediately refreshed. My fatigue left me and I was more alert as if I just got into the airplane. I am a real advocate of O2 especially for anyone over 60years of age. The only thing I tell the pilots new to O2 is put the cannula over your ears prior to TO especially if you are going to use flight following otherwise you need to go off line for a while.

Thanks for your help

I agree with your comments on the exhaust system. I ordered the heat shields and will have the muffler inspected for any cracks etc. I did buy a Carbon Monoxide detector and so far so good.

Best Regards

Bill

I did get the O2 system . Per your recommendations I have the Sky OX the SK11-50 big bottle. I believe you said the refill cost the same no matter what the size. I got a chance to use it on my way to McCAll, ID. I was at 9,500 ft.. I had forgot about until half way through the flight but when I put it on I felt an almost immediately refreshed. My fatigue left me and I was more alert as if I just got into the airplane. I am a real advocate of O2 especially for anyone over 60years of age. The only thing I tell the pilots new to O2 is put the cannula over your ears prior to TO especially if you are going to use flight following otherwise you need to go off line for a while.

Thanks for your help

I agree with your comments on the exhaust system. I ordered the heat shields and will have the muffler inspected for any cracks etc. I did buy a Carbon Monoxide detector and so far so good.

Best Regards

Bill

- donknee

- 100+ Posts

- Posts: 163

- Joined: Sat Aug 26, 2006 6:50 pm

- Location: olympia, wa

- Contact:

One tip I was shown on the mufflers is to take a hose clamp (it took two locked together from my source) in the middle of the muffler and snug it up for extra support. It helps to keep some control to the shape of the expansion and contraction with the heat. That seems to alleviate some of the stress cracks. It has been effective for my Maule.

1976 M5-235-C

- Green Hornet

- 100+ Posts

- Posts: 606

- Joined: Sat Aug 26, 2006 8:53 pm

- Location: No Name City, No Where Land, USA

- Contact:

- yellowbelly

- Posts: 29

- Joined: Sat Aug 26, 2006 7:14 pm

- Contact:

Sojorrn:

Yeah, those aluminum shrouds were a pain, splitting along the lip that hooks over the inboard flange.... until I did this:

You can shop around for the long clamps which I believe I got at Ace Hdw.

Don't clamp them up TOO tight or they will eat their way through the aluminum. In addition to what A64 said, it seems most of the fasteners in the exhaust system need to be looser than you might expect. The riser tabs that meet the stubs coming from the cylinder head, should be little more than finger tight. You should be able to turn them easily with a wrench on the bolt head. Your exhaust pipes from the rear of the muffler should seem almost ridiculously loose, but the rubber strap hangars should stop the downward movement before any bending load is transmitted to the rear bulkhead of the muffler. Once you get them set up properly, they might last a couple of years if you keep knocking on wood regularly.

I agree with 210TC: you should go over the rear bulkheads with a microscope periodically to find any cracks, especially in the radial welds. At least, that's where I found my first cracks. CO poisoning? Run LOP and it won't be a problem.

YB

Yeah, those aluminum shrouds were a pain, splitting along the lip that hooks over the inboard flange.... until I did this:

You can shop around for the long clamps which I believe I got at Ace Hdw.

Don't clamp them up TOO tight or they will eat their way through the aluminum. In addition to what A64 said, it seems most of the fasteners in the exhaust system need to be looser than you might expect. The riser tabs that meet the stubs coming from the cylinder head, should be little more than finger tight. You should be able to turn them easily with a wrench on the bolt head. Your exhaust pipes from the rear of the muffler should seem almost ridiculously loose, but the rubber strap hangars should stop the downward movement before any bending load is transmitted to the rear bulkhead of the muffler. Once you get them set up properly, they might last a couple of years if you keep knocking on wood regularly.

I agree with 210TC: you should go over the rear bulkheads with a microscope periodically to find any cracks, especially in the radial welds. At least, that's where I found my first cracks. CO poisoning? Run LOP and it won't be a problem.

YB

- Green Hornet

- 100+ Posts

- Posts: 606

- Joined: Sat Aug 26, 2006 8:53 pm

- Location: No Name City, No Where Land, USA

- Contact:

-

a64pilot

- 100+ Posts

- Posts: 1773

- Joined: Tue Aug 29, 2006 6:53 am

- Location: ALbany Ga., KABY

- Contact:

- donknee

- 100+ Posts

- Posts: 163

- Joined: Sat Aug 26, 2006 6:50 pm

- Location: olympia, wa

- Contact:

YB- Great photos, and you have the right size clamps. I just put one band in the middle of each one...I think mine are stainless steel. Went and looked at an M6 180 the other day and found the exhaust tube just ahead of the gascolator was cracked all the way around and opened up 1/8" or so. You don't want to let anyone tighten up the bolts for you...the stress from heating and cooling has to go somewhere or it will crack.

1976 M5-235-C

- 210TC

- 100+ Posts

- Posts: 733

- Joined: Fri Jan 12, 2007 7:58 pm

- Location: New Braunfels, Tx

- Contact:

ROP may leave an exhaust smell whereas LOP would be less likely. BOTH CAN KILL YOU.

David

www.Landshort.com

www.Landshort.com

- yellowbelly

- Posts: 29

- Joined: Sat Aug 26, 2006 7:14 pm

- Contact:

There is CO, even LOP.

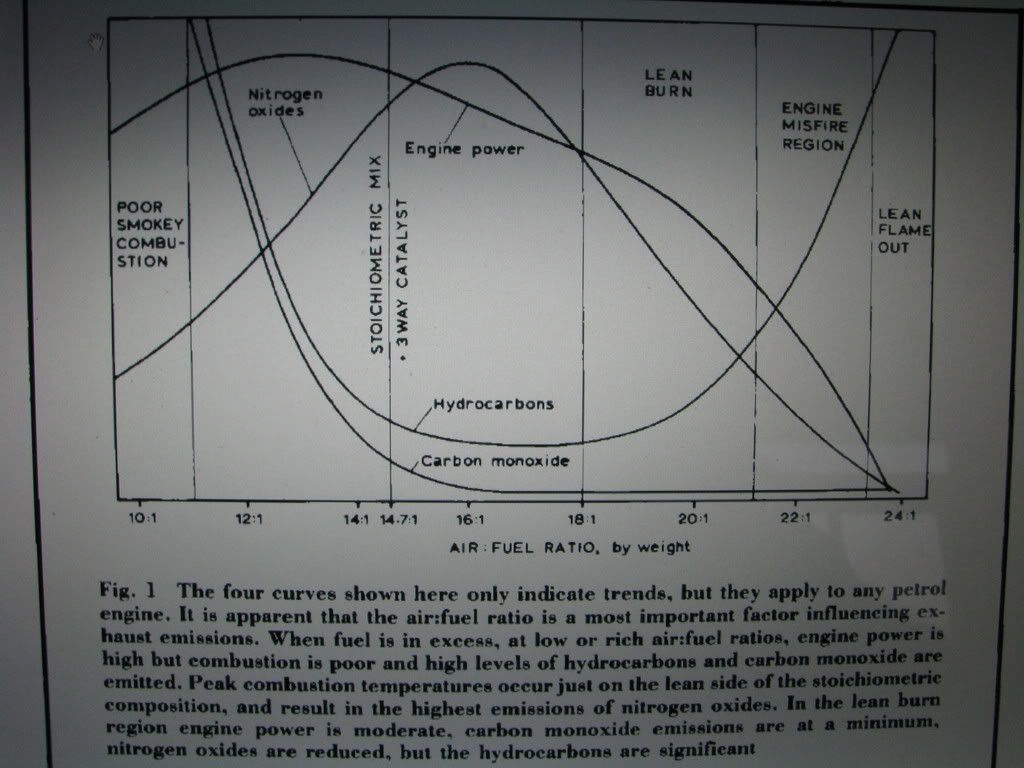

Some, maybe, but compare CO levels at peak power (ROP) to anything to the right of the stoichiometric mixture line (LOP). CO is a product of incomplete combustion, not enough air. If it were my primary concern in my leaky Maule, I know where I would be operating.ROP may leave an exhaust smell whereas LOP would be less likely. BOTH CAN KILL YOU

-

a64pilot

- 100+ Posts

- Posts: 1773

- Joined: Tue Aug 29, 2006 6:53 am

- Location: ALbany Ga., KABY

- Contact:

I don't think these engines will operate anywhere near the "lean burn" point. In fact I think it's only when conditions were just right that Honda could get their Insight into lean burn. There are fewer CO emissions when lean, but still plenty enough to kill you. I'm not sold on LOP, especially with a Lycoming. I've got Gami injectors and the power loss is excessive if you get too much nore than 25 LOP. I think the higher EGT's associated with LOP aren't good for the Exh. valve and exhaust in general. The Conti. IO-520 in my C-210 dosen't lose nearly as much power LOP as my Lycoming and it works well LOP.

Of course you can really only operate an IO LOP anyway and really can't without an engine analyzer and a set of balanced injectors. Lycoming is absolutely dead set against LOP.

http://www.lycoming.com/support/trouble ... SP700A.pdf

Of course you can really only operate an IO LOP anyway and really can't without an engine analyzer and a set of balanced injectors. Lycoming is absolutely dead set against LOP.

http://www.lycoming.com/support/trouble ... SP700A.pdf

Who is online

Users browsing this forum: No registered users and 27 guests