M4 220C cowl egress modification

- Mog

- 100+ Posts

- Posts: 974

- Joined: Fri Nov 26, 2010 8:01 pm

- Location: Dallas, TX

- Contact:

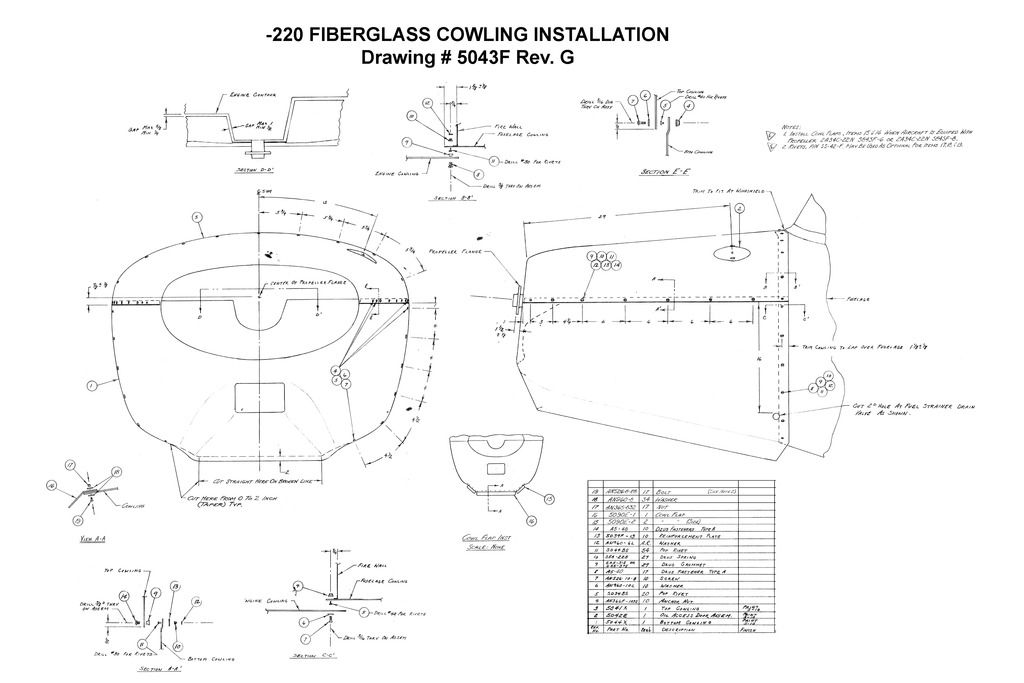

M4 220C cowl egress modification

Can't recal if this has been discussed yet, but my M4 did not have the egress extension when I bought it. It clearly had been installed at one point. I noticed on my last flight that oil temps were on the higher side and concluded that this may have been due to the lack of the egress extension. I tried emailing Maule but my emails were returned undeliverable. So before I call them tomorrow, does anyone have a copy of the drawings or should I just have Bryan bend them up and ship them to me.

-

iceman

- 100+ Posts

- Posts: 593

- Joined: Thu Nov 23, 2006 8:24 am

- Location: El Cajon Calif

- Contact:

- Mog

- 100+ Posts

- Posts: 974

- Joined: Fri Nov 26, 2010 8:01 pm

- Location: Dallas, TX

- Contact:

- n2020u

- Posts: 97

- Joined: Mon Oct 24, 2011 4:31 pm

- Contact:

Re: M4 220C cowl egress modification

Do you have an engine analyzer by chance? I have relatively new and tight baffling in my M-4-220 but no egress flap. My CHT's don't run hotter than 375 at wide open and 85mph (sea level). However, my oil temp can creep up to 200+ degrees during a climb on a hot day. I wonder how much the flap will help. Keep us updated and good luck with you quest for parts!Mog wrote:Can't recal if this has been discussed yet, but my M4 did not have the egress extension when I bought it. It clearly had been installed at one point. I noticed on my last flight that oil temps were on the higher side and concluded that this may have been due to the lack of the egress extension. I tried emailing Maule but my emails were returned undeliverable. So before I call them tomorrow, does anyone have a copy of the drawings or should I just have Bryan bend them up and ship them to me.

Garrett

-

iceman

- 100+ Posts

- Posts: 593

- Joined: Thu Nov 23, 2006 8:24 am

- Location: El Cajon Calif

- Contact:

-

Curtis

- 100+ Posts

- Posts: 117

- Joined: Mon Mar 07, 2011 5:06 pm

- Contact:

OilTemp

If oil temps do not get above 212F then it leaves a lot of moisture in the engine which causes corrosion to metal. Engine oil needs to be at least 212 to 220 degrees F to burn off all the deposits and accumulated water vapor. For every pound of fuel burned in an engine, the combustion process also generates a pound of water! If engine sump temperatures rarely exceed 212 degrees (water’s boiling point), the water will mix with sulfur (another combustion by-product) and create acids that eventually damage bearings and other metal components.

Cold engine oil (180F) causes excessive frictional drag on the bearings and cylinder walls eating away your bearings and cylinders. A quality motor oil will tolerate oil sump temperatures of up to 250 degrees, but starts breaking down over 275 degrees. I would not want to routinely see under-200-degree oil temps because of the destructive adverse affects that it causes to the engine. I run my oil temp 210F-215F. (Franklin max oil operating temp is 230F.)

Cold engine oil (180F) causes excessive frictional drag on the bearings and cylinder walls eating away your bearings and cylinders. A quality motor oil will tolerate oil sump temperatures of up to 250 degrees, but starts breaking down over 275 degrees. I would not want to routinely see under-200-degree oil temps because of the destructive adverse affects that it causes to the engine. I run my oil temp 210F-215F. (Franklin max oil operating temp is 230F.)

Curtis

- Mog

- 100+ Posts

- Posts: 974

- Joined: Fri Nov 26, 2010 8:01 pm

- Location: Dallas, TX

- Contact:

- n2020u

- Posts: 97

- Joined: Mon Oct 24, 2011 4:31 pm

- Contact:

Re: OilTemp

Hmm...I always read 180+ degrees for an hour or more was sufficient burn off accumulated moisture. Both my franklins tend to run about 190 or so in cruise flight and creep up to the 210 mark for hard climbs.Curtis wrote:If oil temps do not get above 212F then it leaves a lot of moisture in the engine which causes corrosion to metal. Engine oil needs to be at least 212 to 220 degrees F to burn off all the deposits and accumulated water vapor. For every pound of fuel burned in an engine, the combustion process also generates a pound of water! If engine sump temperatures rarely exceed 212 degrees (water’s boiling point), the water will mix with sulfur (another combustion by-product) and create acids that eventually damage bearings and other metal components.

Cold engine oil (180F) causes excessive frictional drag on the bearings and cylinder walls eating away your bearings and cylinders. A quality motor oil will tolerate oil sump temperatures of up to 250 degrees, but starts breaking down over 275 degrees. I would not want to routinely see under-200-degree oil temps because of the destructive adverse affects that it causes to the engine. I run my oil temp 210F-215F. (Franklin max oil operating temp is 230F.)

Thanks for the info!

Garrett

-

flyfish1

- Posts: 65

- Joined: Sun Jan 01, 2012 6:43 pm

- Contact:

I also try to run my oil temp about 180. My understanding is that the highest instantaneous oil temp occurs just below the cylinders but the temp probe should be downstream of the oil cooler. By the time the oil makes that journey it has cooled about 40-50 degrees putting the max temp at around 220-240. This is hot enough to boil off the moisture but not hot enough to cause pre mature breakdown of the oil. I say should for the temp probe placement because when I first started flying my M4-220 I was always bumping against the top end of the oil temp. I finally discovered that the oil system was plumbed incorrectly giving me a reading as the oil came out of the engine. Correcting that issue along with installing an engine analyzer and a remote oil filter I find that I have to work to keep my temps hot enough. I have since cut back the length of the aluminum cowling extension but have not removed it insure that the cowling keeps its rigidity as Jeremy suggested.

flyfish1

- Mog

- 100+ Posts

- Posts: 974

- Joined: Fri Nov 26, 2010 8:01 pm

- Location: Dallas, TX

- Contact:

FlyFish, thanks for the response. I think I will check mine this weekend. I highly doubt my cowl is collapsing due to reinforcement. But I could be wrong. I have tried to contact Maule several times and cannot get anyone to answer the phone. I was able to snap some pics of a friends 220C so I certainly know what needs to be made at this point.

-

Curtis

- 100+ Posts

- Posts: 117

- Joined: Mon Mar 07, 2011 5:06 pm

- Contact:

-

stick_rudder

- 100+ Posts

- Posts: 120

- Joined: Mon Dec 02, 2013 7:25 pm

- Location: Alaska

- Contact:

- Mog

- 100+ Posts

- Posts: 974

- Joined: Fri Nov 26, 2010 8:01 pm

- Location: Dallas, TX

- Contact:

- Mog

- 100+ Posts

- Posts: 974

- Joined: Fri Nov 26, 2010 8:01 pm

- Location: Dallas, TX

- Contact:

- Duane

- 100+ Posts

- Posts: 762

- Joined: Mon Apr 07, 2008 1:58 pm

- Location: moultrie ga

- Contact:

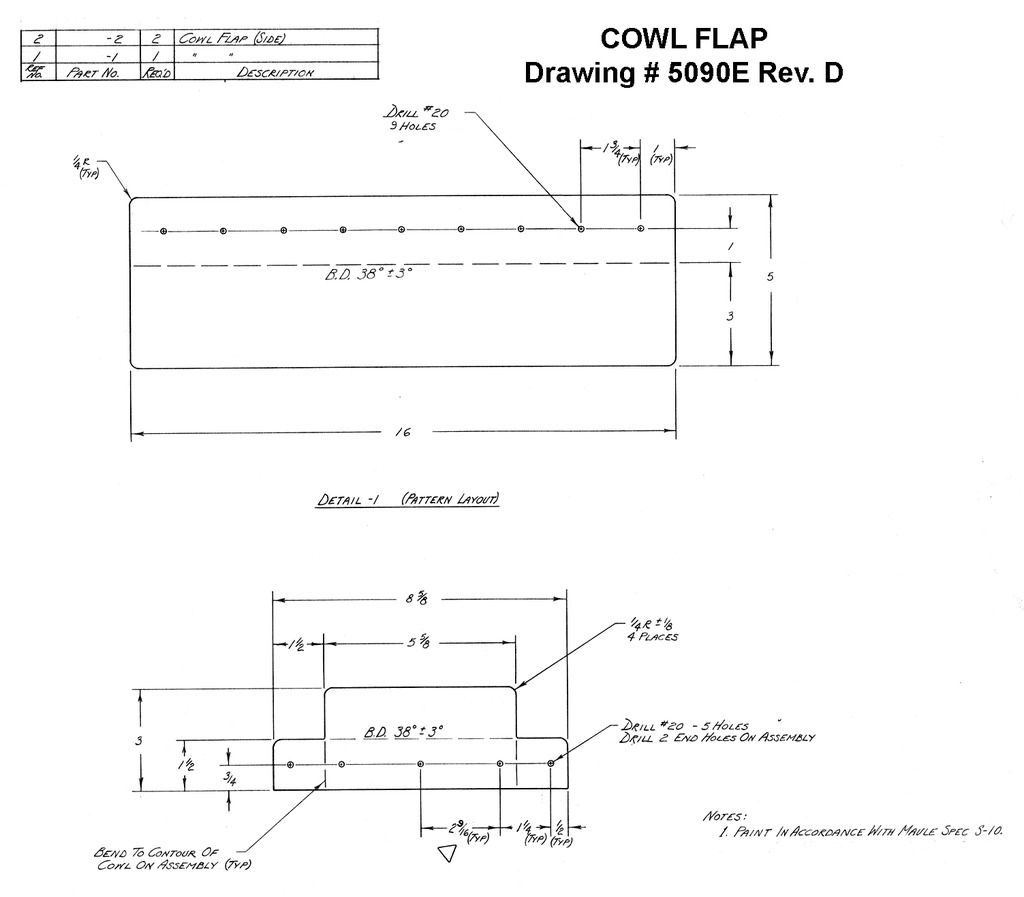

I looked into this and found something I had never known existed. To be technically legal, the one Mog drew up in autocad is 9213F rev A and the other one is 5090E rev D. The 5090E one is approved for the M-4 and M-5 Franklin engines and the 9213F is approved for all M-7, MT-7 and the M-9 versions.

I had never seen the 5090E cowl flap before as far as I can remember. Would one work in place of the other? Most likely. This is just what is on our TC.

I had never seen the 5090E cowl flap before as far as I can remember. Would one work in place of the other? Most likely. This is just what is on our TC.

Who is online

Users browsing this forum: Google [Bot] and 7 guests

[/URL]

[/URL] [/URL]

[/URL]